Knowing about the properties of materials is important in industries like construction and manufacturing. Specifically, the hardness of a material is a key aspect to consider. The quality and level of hardness play a role in establishing how well a material can resist deformation and whether it is suitable for use. Tests for hardness provide information about this feature, assisting experts in making well-informed choices. This article explores the different kinds of hardness tests and how they work.

Types of Hardness Tests

Various methods are available to measure the hardness of materials, with each method designed for a specific use based on the material and its application needs. Known hardness tests, such as Brinell’s method, use techniques like applying force to determine how materials respond to it. If you’ve ever wondered, “what are hardness tests?”, you’re at the right place.

Brinell Hardness Test

The Brinell test is an old-school technique that involves pressing an indenter, usually made of toughened steel or carbide, into the surface of the material being tested. The size of the resulting dent gives a clue to how hard the material is. It’s good for materials with uneven surfaces and gives consistent results even if there are some differences in the texture.

Rockwell Hardness Test

The Rockwell test provides a more accurate method. By utilizing a diamond or a steel ball, this assessment gauges the depth of an indentation under a set force. The Rockwell test yields precise outcomes, making it well-suited to quality assurance procedures. Its adaptability spans across metals, plastics, and ceramics, accommodating materials.

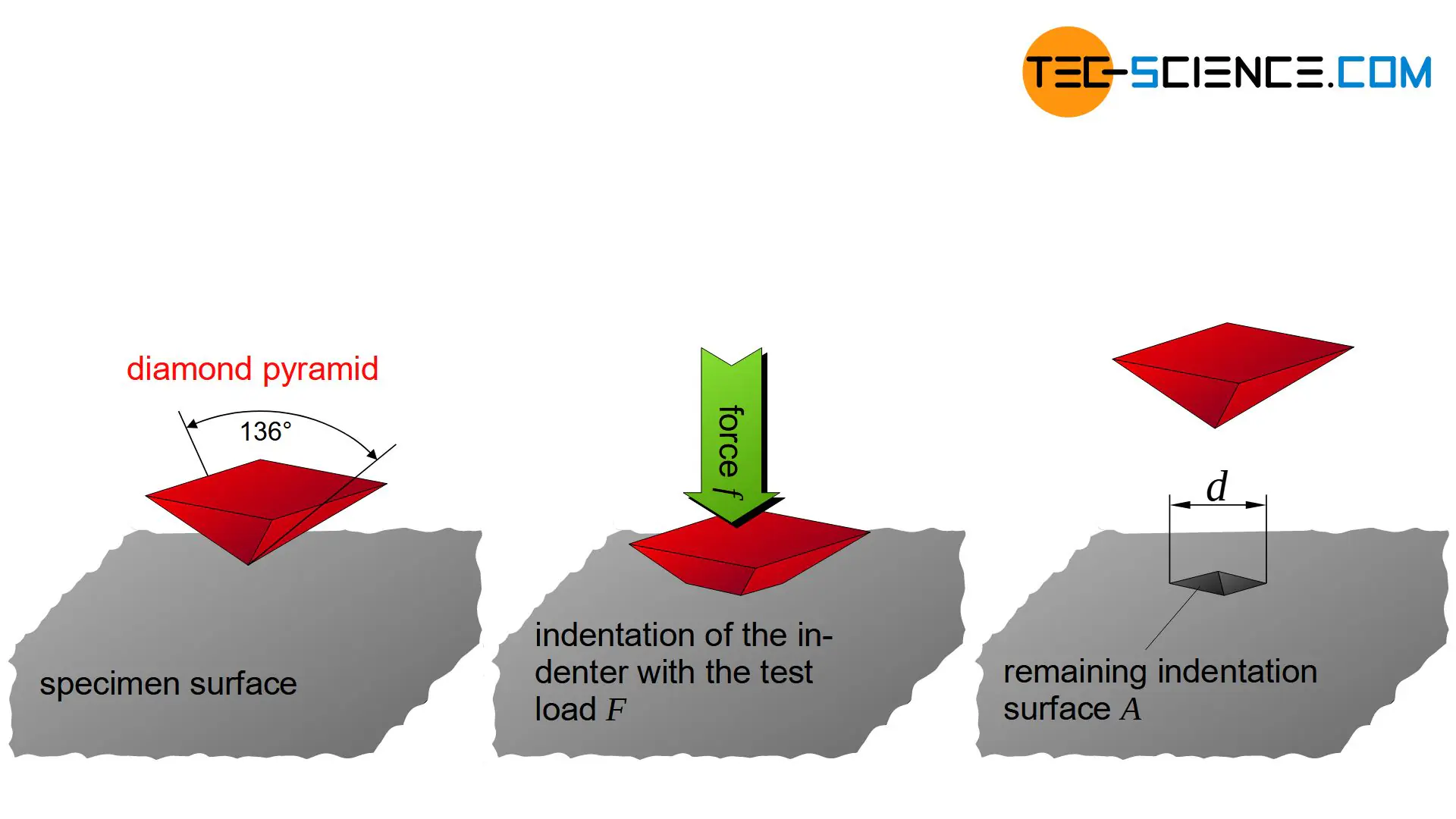

Vickers Hardness Test

The Vickers test is another method that utilizes a diamond pyramid indenter to assess hardness levels in materials. It measures the length of the impression it leaves behind on the surface. This test is known for its accuracy across a variety of scales. It is valuable for evaluating both micro and macro hardness levels effectively. Its high level of precision makes it particularly suitable for assessing hardness in materials and coatings situations where other methods may not be as reliable.

Knoop Hardness Test

When it comes to substances like ceramics or delicate coatings, the Knoop test provides a straightforward method to assess their durability. By using a bespoke designed diamond tool with an elongated shape, this approach gauges the length of the indentation made. The Knoop test stands out for its ability to gauge the hardness of surfaces without inflicting harm, ensuring that the integrity of the material remains intact.

Choosing the Right Test

Choosing the hardness test relies on factors such as the type of material used, the size of the sample, and the level of accuracy desired. All these aspects contribute to making a well-informed decision. Each testing method has advantages tailored to its use, which aids professionals in selecting the most suitable method based on their requirements.

Applications of Hardness Testing

Hardness testing is utilized in a range of industries. One example is in the aviation industry, where these tests verify that components are durable and can withstand long-term use. In aerospace applications, hardness assessments are crucial to ensure materials can tolerate extreme environments. Similarly, in the construction industry, hardness evaluations help assess the appropriateness of materials for needs.

Advancements in Hardness Testing

Technology is constantly progressing, which leads to advancements in hardness testing methods and tools getting better and more efficient over time. New innovations are being introduced regularly to improve accuracy and to speed up the process of obtaining results accurately through systems that make everything more streamlined and efficient. This ultimately helps to keep hardness testing relevant and useful for various industries by adjusting to the changing requirements of modern businesses.

In Conclusion

Testing the hardness of materials is crucial for evaluating their properties and characteristics in the industry field today. There are several methods like Brinell and Rockwell that have their benefits along with Vickers and Knoop techniques, which provide distinct advantages to professionals in making well-informed choices regarding material suitability and efficiency levels. As industries progress further with time, carrying out hardness tests continues to be vital to maintaining standards and safety in applications.